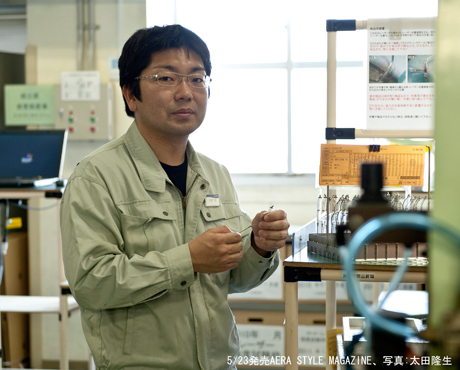

A mission for Hiroyuki TADA was to develop a better and advanced material which was safe, processable to achieve the required design, and of course above all, create comfortable eyewear.

Charmant Group was already successful in creating comfortable and safe eyewear, having used a Titanium alloy named Z-titanium which was also used in the medical field because of its highly flexible and human-safe properties. However, the Group set a higher goal and TADA embarked on the project.

Developing a new material is extremely difficult as it takes at least 10 to 20 years in development to perfect. There was an opinion in the Group that such a development should be left for material suppliers rather than taking it on by ourselves. However, TADA initiated the project with the belief that the frame manufacture should know in its own experience the material truly required to further evolve the products.

Hiroyuki TADA, in charge of development Excellence Titan

The project turned out to be a tough journey though TADA received support from experts of Tohoku University Institute for Materials Research, the world authority of Metallurgical Research, for higher knowledge and expertise.

His team faced many obstacles even after success on a material stage. When using the new material for a commercial product it should have been a high quality material which would ensure the long lasting benefit for the user.

There were unsatisfactory cases, for example – the material lost original flexibility after surface treatments were applied to the frame or the beneficial properties changed through thermal processes. The result was that the finished eyewear did not pass the severe quality test that the Group has set for themselves.

Through continued trial and error his team overcame the obstacles and continued successfully on their journey. The strong determination of the team was to provide eyeglass wearers with comfortable eyewear. This determination along with the experience of the Tohoku University Institute for Materials Research achieved their goal together. In spring 2009, having developed Excellence Titan, the first commercial product was born. Finally after 8 years of research and development the eyewear with a revolutionary design and wearing comfort made its debut.

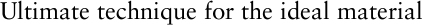

Hiroshi NAKAMURA, in charge of development joining technologies

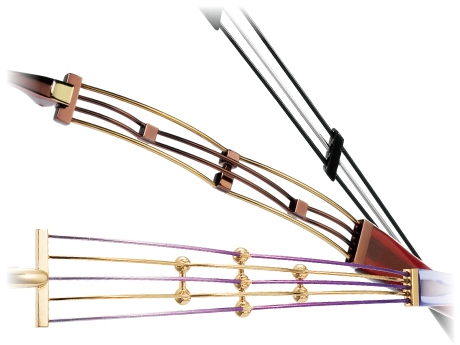

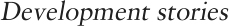

Completely new techniques were needed to make the best use of the characteristics of Excellence Titan. Coincidentally there was an on-going research on the development of new welding techniques by the Group. Under the support of Fukui Prefecture Industrial Support Center., Hiroshi NAKAMURA began the research on joining new technologies with the Joining & Welding Research Institute of Osaka University

Normally, brazing was used to join metal pieces during the eyewear fabrication process. However, the high heat levels generated during brazing tended to weaken the base material and could cause structural changes in the metal and result in the parts detaching.

Naturally, in order to prevent a host of problems, brazing technology had been improved and was considered to have reached a high level of perfection. However, in order to broaden the scope of eyewear possibilities, the development of new joining technology other than brazing would be indispensable.

The laser welding technique became our opportunity since it resulted in high-strength joining and was already used for automobile and aircraft parts.

Applying that same technology on a much smaller scale was never easy and there was an endless series of challenges in its development. When joining automotive parts, additional parts are placed over the welded sections, so that the aesthetics of the welded sections are not as important. By contrast, eyewear being extremely fine and worn on the face, everyone is most concerned about the finish.

Having the aspiration to develop new joining technology to expand the possibilities of eyewear, NAKAMURA did his utmost in collaboration. In 2009, the precision laser welding technology was successfully developed for practical use having enabled the welding of even the smallest of parts. At the same time, the Excellence Titan material was also ready.

The flagship brand, LineArt CHARMANT with the unique beauty and the outstanding feature of Excellence Titan could only be accomplished by using this new and innovative technology. It allows strong welding to even the smallest parts of the frame without compromising the materials integrity. The precision laser welding offers limitless design options ensuring frames that are both aesthetic and comfortable with seamless joints.

The passion of the experts made the new material come true and the innovative technique achieved the sophisticated level of eyewear that provides a never-experienced wearing comfort. In order to continue to expand the possibilities of new innovative eyewear, further development of technologies will be pursued.